罚函数法,Lagrangian乘数法,递增Lagrangian乘数法, 内点法

3 渐增Lagrangian乘数法/内点法的实装方法

前述第1节讲述的四种方法中,罚函数法,Lagrangian乘数法的解可以从所得方程直接解出。而递增Lagrangian乘数法和内点法需要使用迭代法求解。

在本节中,将以一自由度的接触问题为例,又易到难地讲解采用递增Lagrangian乘数法和内点法的接触算法。由于接触问题的解析一般用增分法求解,而在第一节中我们给出的是全量公式。在这一节中给出的算法是基于增分法的,因此第一节中给出的公式也要相应改写。

为显示算法实现,从本节开始将添加一些用python语言编写的程序附件。在之后的算法实现中。将大量使用迭代计算。为了明示迭代步数,本文将以上下标n,k表示各迭代步。

在本节中,将以一自由度的接触问题为例,又易到难地讲解采用递增Lagrangian乘数法和内点法的接触算法。由于接触问题的解析一般用增分法求解,而在第一节中我们给出的是全量公式。在这一节中给出的算法是基于增分法的,因此第一节中给出的公式也要相应改写。

为显示算法实现,从本节开始将添加一些用python语言编写的程序附件。在之后的算法实现中。将大量使用迭代计算。为了明示迭代步数,本文将以上下标n,k表示各迭代步。

3.1 考虑接触非线性的基于递增Lagrangian乘数法的实装方法

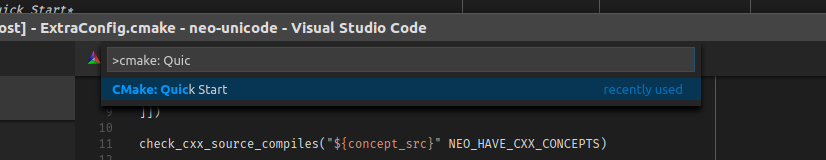

图1 一自由度的接触问题

S0: 初始状态的求解

1) 初期接触状态的判定:无接触,由(0.4)式得到物体m的位移量$x_0=F/K$

2) 接触状态的判定: 如$g=g_0+x_0>=0$计算结束。否则判定进入接触,继续下一步计算。

以下进入递增Lagrangian乘数法求解。在这里我们令罚函数$\varepsilon_N=10000$,收束判定值TOL=1.e-10

在此,对应于增分解析,我们将(3.1)改写为

$J=1/2K(x+x_0)^2 -F(x+x_0) +\lambda (x+g)+1/2\varepsilon_N (x+g)^2=0$

在这里x表示下一步的位移。相应地,式(3.4)改变为

$ x=(F-\varepsilon_Ng_0-\lambda-Kx_0)/(K+\varepsilon_N) $

在此,对应于增分解析,我们将(3.1)改写为

$J=1/2K(x+x_0)^2 -F(x+x_0) +\lambda (x+g)+1/2\varepsilon_N (x+g)^2=0$

在这里x表示下一步的位移。相应地,式(3.4)改变为

$ x=(F-\varepsilon_Ng_0-\lambda-Kx_0)/(K+\varepsilon_N) $

S1: k=0, $\lambda_0=0$, $x_0=0$

S2: if $g+x_k<=TOL$

goto S3

else

$ x_{k+1}=(F-\varepsilon_Ng_0-\lambda-Kx_0)/(K+\varepsilon_N) $

$\lambda_{k+1}=\lambda_{k}+ \varepsilon_N *(g+x_{k+1})$

k=k+1; goto S2

S3: end

计算源码从此下载。

计算过程如下。

iter, disp incr , gap , Lagrangian

0, 0.000000000, -1.0000000e-01, 0.000000000

1, 0.090909091, -9.0909091e-03, -9.090909091

2, 0.099173554, -8.2644628e-04, -9.917355372

3, 0.099924869, -7.5131480e-05, -9.992486852

4, 0.099993170, -6.8301346e-06, -9.999316987

5, 0.099999379, -6.2092132e-07, -9.999937908

6, 0.099999944, -5.6447393e-08, -9.999994355

7, 0.099999995, -5.1315812e-09, -9.999999487

8, 0.100000000, -4.6650737e-10, -9.999999953

9, 0.100000000, -4.2409770e-11, -9.999999996

Displacement= -0.100000000042

Final gap= -4.24097701401e-11

Contact force= -9.99999999576

S2: if $g+x_k<=TOL$

goto S3

else

$ x_{k+1}=(F-\varepsilon_Ng_0-\lambda-Kx_0)/(K+\varepsilon_N) $

$\lambda_{k+1}=\lambda_{k}+ \varepsilon_N *(g+x_{k+1})$

k=k+1; goto S2

S3: end

计算源码从此下载。

计算过程如下。

iter, disp incr , gap , Lagrangian

0, 0.000000000, -1.0000000e-01, 0.000000000

1, 0.090909091, -9.0909091e-03, -9.090909091

2, 0.099173554, -8.2644628e-04, -9.917355372

3, 0.099924869, -7.5131480e-05, -9.992486852

4, 0.099993170, -6.8301346e-06, -9.999316987

5, 0.099999379, -6.2092132e-07, -9.999937908

6, 0.099999944, -5.6447393e-08, -9.999994355

7, 0.099999995, -5.1315812e-09, -9.999999487

8, 0.100000000, -4.6650737e-10, -9.999999953

9, 0.100000000, -4.2409770e-11, -9.999999996

Displacement= -0.100000000042

Final gap= -4.24097701401e-11

Contact force= -9.99999999576

3.2 考虑接触非线性的的基于内点法的实装方法

这里的算法在(1.4)节给出的primal-dual算法。计算源码从此下载。

计算过程如下。

iter, displacement, Lagrangian, barrier parameter

1, -0.038196601, 16.180339887, 1.0000000e+00

2, -0.075838015, 12.416198487, 3.0000000e-01

3, -0.091690481, 10.830951895, 9.0000000e-02

4, -0.097369211, 10.263078947, 2.7000000e-02

5, -0.099196457, 10.080354318, 8.1000000e-03

6, -0.099757588, 10.024241236, 2.4300000e-03

7, -0.099927153, 10.007284693, 7.2900000e-04

8, -0.099978135, 10.002186522, 2.1870000e-04

9, -0.099993439, 10.000656057, 6.5610000e-05

10, -0.099998032, 10.000196826, 1.9683000e-05

11, -0.099999410, 10.000059049, 5.9049000e-06

12, -0.099999823, 10.000017715, 1.7714700e-06

13, -0.099999947, 10.000005314, 5.3144100e-07

14, -0.099999984, 10.000001594, 1.5943230e-07

15, -0.099999995, 10.000000478, 4.7829690e-08

16, -0.099999999, 10.000000143, 1.4348907e-08

17, -0.100000000, 10.000000043, 4.3046721e-09

18, -0.100000000, 10.000000013, 1.2914016e-09

19, -0.100000000, 10.000000004, 3.8742049e-10

20, -0.100000000, 10.000000001, 1.1622615e-10

Displacement= -0.0999999999884

Final gap= 1.16226195335e-11

Contact force= 10.0000000012

3.3 考虑材料非线性和接触非线性的基于递增Lagrangian乘数法的实装方法

在前述算例中我们只考虑了接触非线性,而在实际应用中,接触非线性往往和材料非线性,几何非线性等并存。这一节将考虑非线性弹簧,其弹性系数K=100-1/30x。以此演示和其他非线性现象共存时接触解析的基于递增Lagrangian乘数法的实装方法。

此时的泛函J的变分为

$J=1/2K_0^2-1/30 x^3+ (\lambda+1/2\varepsilon_Nx) x -F x$

$\delta J=(K_0-0.1x) x\delta x+ (\lambda+\varepsilon_Nx)\delta x -(F-\varepsilon_Ng_0) \delta x=0$

基于变分$\delta x$的任意性,可得

$(K-0.1x+\varepsilon_N)x+\lambda-(F+\varepsilon_Ng_0)=0$

这是在这一节要解的方程。采用Newton迭代法,上式的增分形式为

$\Delta x^{n+1}=(F-(K_0-0.1x^n)x^n-\lambda-\varepsilon_N(x^n+g_0))/(K_0-0.2x^n+\varepsilon_N)$

iter, disp incr , gap , Lagrangian

0, -0.196152423, -9.6152423e-02, 0.000000000

internal loop, disp= 0.0870619064302

internal loop, disp= 6.89056837473e-07

1, -0.109089827, -9.0898272e-03, -9.089827219

internal loop, disp= 0.0082633153912

internal loop, disp= 6.20737540768e-09

2, -0.100826506, -8.2650562e-04, -9.916332840

internal loop, disp= 0.000751354971978

internal loop, disp= 5.13203608441e-11

3, -0.100075151, -7.5150597e-05, -9.991483437

internal loop, disp= 6.83174816365e-05

internal loop, disp= 4.24294993083e-13

4, -0.100006833, -6.8331151e-06, -9.998316552

internal loop, disp= 6.21180988284e-06

5, -0.100000621, -6.2130523e-07, -9.998937857

internal loop, disp= 5.64812673181e-07

6, -0.100000056, -5.6492560e-08, -9.998994350

internal loop, disp= 5.13559388072e-08

7, -0.100000005, -5.1366210e-09, -9.998999486

internal loop, disp= 4.66957053199e-09

8, -0.100000000, -4.6705044e-10, -9.998999953

internal loop, disp= 4.24583585173e-10

9, -0.100000000, -4.2466849e-11, -9.998999996

Displacement= -0.100000000042

Final gap= -4.24668494814e-11

Contact force= -9.99899999575

此时的泛函J的变分为

$J=1/2K_0^2-1/30 x^3+ (\lambda+1/2\varepsilon_Nx) x -F x$

$\delta J=(K_0-0.1x) x\delta x+ (\lambda+\varepsilon_Nx)\delta x -(F-\varepsilon_Ng_0) \delta x=0$

基于变分$\delta x$的任意性,可得

$(K-0.1x+\varepsilon_N)x+\lambda-(F+\varepsilon_Ng_0)=0$

这是在这一节要解的方程。采用Newton迭代法,上式的增分形式为

$\Delta x^{n+1}=(F-(K_0-0.1x^n)x^n-\lambda-\varepsilon_N(x^n+g_0))/(K_0-0.2x^n+\varepsilon_N)$

S0: 初始状态的求解

1) 初期接触状态的判定:无接触,由$(K+0.1x)x+\lambda=F$求解物体m的初始位移量$x_0$。由于该式非线性,我们需要使用迭代计算。

2) 接触状态的判定: 如$g=g_0+x_0>=0$计算结束。否则判定进入接触,继续下一步计算。

以下进入递增Lagrangian乘数法求解。在此我们使用两重迭代(nested augmented lagrangian algorithm),分别处理材料非线性和接触非线性

S1: k=0, $\lambda_0=0$, $x_0^0=0$

S2: 外部循环,更新计算Lagrangian乘数

if $g+x_k<=TOL$

goto S5

else

goto S3

S3 内部循环,Lagrangian乘数不变,更新计算位移增量

n = 0

$df =F-\varepsilon_Ng_0-\lambda-(K_0-0.1 x_k^n) x_k^n$

if df<TOL

goto S4

else

$ \Delta x_{k+1}^{n+1}=df/(K-0.2x_k^n+\varepsilon_N) $

$x_{k+1}^{n+1}= x_{k+1}^n + \Delta x_{k+1}^{n+1}$

n = n+1

goto S3

S4 $\lambda_{k+1}=\lambda_{k}+ \varepsilon_N *(g+x_{k+1})$

k=k+1; goto S2

S5 end

计算源码从此下载。

计算过程如下。

Initial displacement and contact gap -0.196152422706 0.1S1: k=0, $\lambda_0=0$, $x_0^0=0$

S2: 外部循环,更新计算Lagrangian乘数

if $g+x_k<=TOL$

goto S5

else

goto S3

S3 内部循环,Lagrangian乘数不变,更新计算位移增量

n = 0

$df =F-\varepsilon_Ng_0-\lambda-(K_0-0.1 x_k^n) x_k^n$

if df<TOL

goto S4

else

$ \Delta x_{k+1}^{n+1}=df/(K-0.2x_k^n+\varepsilon_N) $

$x_{k+1}^{n+1}= x_{k+1}^n + \Delta x_{k+1}^{n+1}$

n = n+1

goto S3

S4 $\lambda_{k+1}=\lambda_{k}+ \varepsilon_N *(g+x_{k+1})$

k=k+1; goto S2

S5 end

计算源码从此下载。

计算过程如下。

iter, disp incr , gap , Lagrangian

0, -0.196152423, -9.6152423e-02, 0.000000000

internal loop, disp= 0.0870619064302

internal loop, disp= 6.89056837473e-07

1, -0.109089827, -9.0898272e-03, -9.089827219

internal loop, disp= 0.0082633153912

internal loop, disp= 6.20737540768e-09

2, -0.100826506, -8.2650562e-04, -9.916332840

internal loop, disp= 0.000751354971978

internal loop, disp= 5.13203608441e-11

3, -0.100075151, -7.5150597e-05, -9.991483437

internal loop, disp= 6.83174816365e-05

internal loop, disp= 4.24294993083e-13

4, -0.100006833, -6.8331151e-06, -9.998316552

internal loop, disp= 6.21180988284e-06

5, -0.100000621, -6.2130523e-07, -9.998937857

internal loop, disp= 5.64812673181e-07

6, -0.100000056, -5.6492560e-08, -9.998994350

internal loop, disp= 5.13559388072e-08

7, -0.100000005, -5.1366210e-09, -9.998999486

internal loop, disp= 4.66957053199e-09

8, -0.100000000, -4.6705044e-10, -9.998999953

internal loop, disp= 4.24583585173e-10

9, -0.100000000, -4.2466849e-11, -9.998999996

Displacement= -0.100000000042

Final gap= -4.24668494814e-11

Contact force= -9.99899999575

3.4 摩擦接触问题的求解方法

图2 一自由度的摩擦接触问题

在这里我们采用库仑摩擦定理

(4.1)$\begin{eqnarray}

f<=-\mu*mg*sign \dot x \\

x=0;\ if\ f<\mu*mg

\end{eqnarray}$

在$f<\mu*mg$是为粘结摩擦状态,否则称为滑动摩擦状态。

此时的泛函J为*1

(4.2)$\begin{eqnarray}

在粘结摩擦状态下: J=1/2K_0 x^2 +0.1/3 x^3 -F x +\lambda x+1/2\varepsilon_T x^2 \\

在滑动摩擦状态下: J=1/2K_0 x^2 +0.1/3 x^3 -F x +\mu*mg x

\end{eqnarray}$

在这里,我们使用递增Lagrangian乘数法处理条件$x=0;\ if\ f<\mu*mg$,该泛函与式(3.1)相同。滑动摩擦状态下的泛函则对应于式(0.1)。

由于要考虑粘结和滑动的状态变化,其解法要相应地复杂一些。这一问题的解法如下:

S1: k=0, $\lambda_0=0$, $x_0^0=0$

S2: 外部循环,更新计算Lagrangian乘数

if $\Delta x<=TOL$

goto S5

else

goto S3

S3 内部循环,Lagrangian乘数不变,更新计算位移增量

n=0

$fric=\lambda_k^n$

if 粘结摩擦

$df = F-\lambda_k-\varepsilon_T x -(K_0+0.1x_k)x_k$

$\Delta x_{n+1} =df/(K_0+0.2x_n+\varepsilon_T)$

$fric = fric+\varepsilon_T x$

if $fric>\mu*mg$

$fric = \mu*mg$进入滑动摩擦

else

$df = F-fric-(K_0+0.1x_k)x_k$

$\Delta x_{n+1} =df/(K_0+0.2x_n)$

$fric = \mu*mg$

$ x=x+\Delta x$

if df<TOL

goto S4

else

n=n+1; goto S3

S4 if 粘结摩擦

$\lambda_{k+1}=\lambda_{k}+ \varepsilon_T *x_{k+1}$

else

$\lambda_{k+1}=\mu*mg$

k=k+1; goto S2

S3 end

在这里我们显示的是一维问题。在2维,3维计算中,我们需要同时考虑3.3节所示不可贯入条件和本节所示摩擦条件,此时我们需要结合3.3和3.4节的内容。其详细将在后续博文中论及。

-----Step: 1

External Force= 10.0 0.0

Iter, Displacement , Lagrangian

internal loop, disp= 0.00909090909091 0.00909090909091

internal loop, disp= 0.00909090157777 0.00909090157777

internal loop, disp= 0.00909090157777 0.00909090157777

1, 0.009090902, 9.090901578

internal loop, disp= 0.000826459258203 0.000826459258203

internal loop, disp= 0.000826453049022 0.000826453049022

internal loop, disp= 0.000826453049022 0.000826453049022

2, 0.000826453, 9.917354627

internal loop, disp= 7.51322082622e-05 7.51322082622e-05

internal loop, disp= 7.51321569456e-05 7.51321569456e-05

internal loop, disp= 7.51321569456e-05 7.51321569456e-05

3, 0.000075132, 9.992486784

internal loop, disp= 6.830197019e-06 6.830197019e-06

internal loop, disp= 6.83019659489e-06 6.83019659489e-06

internal loop, disp= 6.83019659489e-06 6.83019659489e-06

4, 0.000006830, 9.999316980

internal loop, disp= 6.20926970885e-07 6.20926970885e-07

internal loop, disp= 6.20926967378e-07 6.20926967378e-07

5, 0.000000621, 9.999937907

internal loop, disp= 5.64479061917e-08 5.64479061917e-08

internal loop, disp= 5.64479061623e-08 5.64479061623e-08

6, 0.000000056, 9.999994355

internal loop, disp= 5.13162783284e-09 5.13162783284e-09

internal loop, disp= 5.13162783284e-09 5.13162783284e-09

7, 0.000000005, 9.999999487

internal loop, disp= 4.66511621933e-10 4.66511621933e-10

internal loop, disp= 4.66511620318e-10 4.66511620318e-10

8, 0.000000000, 9.999999953

internal loop, disp= 4.24101488013e-11 4.24101488013e-11

internal loop, disp= 4.24101488013e-11 4.24101488013e-11

9, 0.000000000, 9.999999996

internal loop, disp= 3.85546854484e-12 3.85546854484e-12

internal loop, disp= 3.85546692997e-12 3.85546692997e-12

10, 0.000000000, 10.000000000

Total Displacement & Displacement of current step= 3.85546692997e-12 3.85546692997e-12

frictional force= 9.99999999961

Spring force= 3.85546692997e-10

Reaction force= 10.0

-----Step: 2

External Force= 20.0 9.99999999961

Iter, Displacement , Lagrangian

From stick to slip state: 19.0909090905 > 10.0

internal loop, disp= 0.00909090909476 0.00909090909091

internal loop, disp= 0.0999982644944 0.0999982644905

internal loop, disp= 0.0999900019996 0.0999900019957

internal loop, disp= 0.0999900019995 0.0999900019956

11, 0.099990002, 10.000000000

internal loop, disp= 0.0999900019995 0.0999900019956

12, 0.099990002, 10.000000000

Total Displacement & Displacement of current step= 0.0999900019995 0.0999900019956

frictional force= 10.0

Spring force= 10.0

Reaction force= 20.0

-----Step: 3

External Force= 10.0 10.0

Iter, Displacement , Lagrangian

From slip to stick state: -89.980005998 < 10.0

internal loop, disp= 9.99600149944e-06 -0.099980005998

internal loop, disp= 0.0909000016525 -0.00909000034697

internal loop, disp= 0.0908992506656 -0.00909075133393

internal loop, disp= 0.0908992506656 -0.00909075133393

13, 0.090899251, -9.090751334

internal loop, disp= 0.0991634334768 -0.000826568522726

internal loop, disp= 0.0991634272681 -0.000826574731406

internal loop, disp= 0.0991634272681 -0.000826574731406

14, 0.099163427, -9.917326065

internal loop, disp= 0.0999148452942 -7.51567052527e-05

internal loop, disp= 0.0999148452429 -7.51567565817e-05

internal loop, disp= 0.0999148452429 -7.51567565817e-05

15, 0.099914845, -9.992482822

internal loop, disp= 0.0999831683259 -6.83367359656e-06

internal loop, disp= 0.0999831683255 -6.83367402093e-06

internal loop, disp= 0.0999831683255 -6.83367402093e-06

16, 0.099983168, -9.999316496

internal loop, disp= 0.0999893806435 -6.21356025034e-07

internal loop, disp= 0.0999893806435 -6.21356028544e-07

17, 0.099989381, -9.999937852

internal loop, disp= 0.0999899455023 -5.64971807554e-08

internal loop, disp= 0.0999899455023 -5.64971807833e-08

18, 0.099989946, -9.999994349

internal loop, disp= 0.0999899968625 -5.13704107356e-09

internal loop, disp= 0.0999899968625 -5.1370410737e-09

19, 0.099989997, -9.999999486

internal loop, disp= 0.0999900015324 -4.67088634118e-10

internal loop, disp= 0.0999900015324 -4.67088632216e-10

20, 0.099990002, -9.999999953

internal loop, disp= 0.099990001957 -4.24703217975e-11

internal loop, disp= 0.099990001957 -4.24703219933e-11

21, 0.099990002, -9.999999996

internal loop, disp= 0.0999900019956 -3.86164012211e-12

internal loop, disp= 0.0999900019956 -3.8616413703e-12

22, 0.099990002, -10.000000000

Total Displacement & Displacement of current step= 0.0999900019956 -3.8616413703e-12

frictional force= 3.86238596661e-10

Spring force= 9.99999999961

Reaction force= 10.0

第一加载步处于粘结摩擦状态,可以看出此时的位移为零,但出现摩擦力。第二加载步则进入滑动摩擦,可以看出明显的位移,同时摩擦力满足库仑摩擦定理。在第3加载步,物体滑动方向逆转,再次进入粘结摩擦状态。在这一步,位移增分为零,摩擦力回零。

下章预告: 动力学数值解析中接触条件的处理方法

*1 对于摩擦状态变化的问题,没有统一的泛函表达式,需要使用虚位移原理公式。这一内容将在后续博文中论及。

没有评论:

发表评论